Realizing the potential of ethanol for fertilizers and fuel

“Corn? You want me to work on corn?!”

Upon arriving to graduate school, my advisor proposed a project to me that would involve taking ethanol, the alcohol that we drink for a good time, to next generation fertilizers.

“Since the majority of ethanol in the United States comes from corn, a renewable resource, there has to be a way to make fertilizer out of it,” he said while I looked unimpressed. My motivation for coming to graduate school was to work on projects that had real world impacts – I was not about to be the “Corn Guy.”

Flash forward two years and I’m the Corn Guy.

My name is Rice Rander, and I am a rising third year PhD student in USC’s Department of Chemistry. I joined Professor Travis Williams’s lab back in fall 2021. I was initially drawn to the lab because of its focus on designing and testing catalysts, or molecules that help reactions work that normally wouldn’t, for the production of hydrogen as a next generation fuel. Ultimately, the goal of our research is to store energy in the form of chemical bonds which can be released as needed, and hydrogen and various organic molecules are perfect for this. I love this chemistry and it is amazing that I now get to be part of the team doing impactful research that helps us develop a more sustainable society for the future. While I initially had hesitations on synthesizing fertilizers from ethanol, I couldn’t imagine doing anything else now.

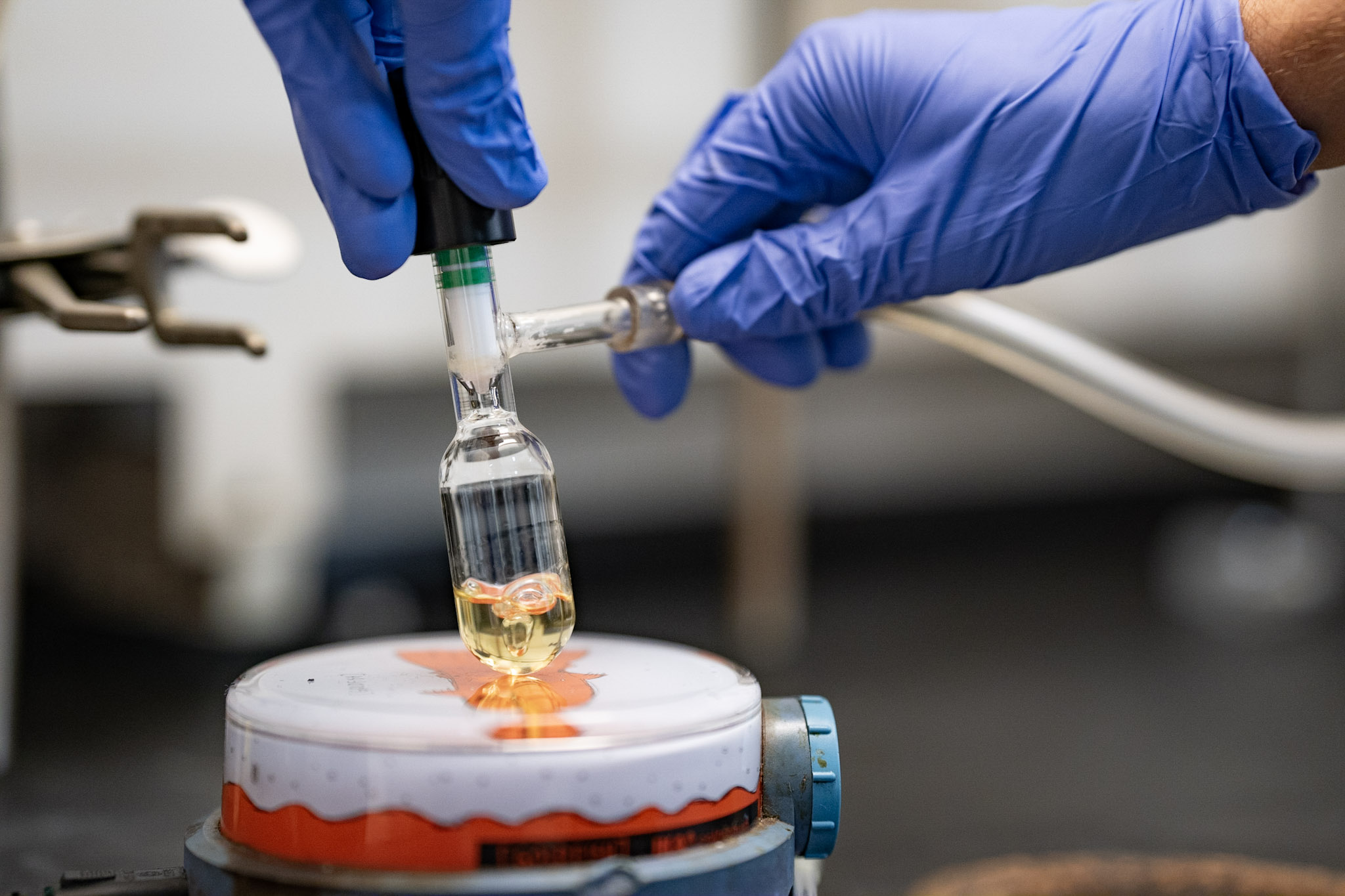

Our goal has been to find catalysts that help us synthesize potassium acetate (a compound related to vinegar) as it is a great potassium source for plants. In our lab, we work mostly with organometallics (which is just a complicated name for saying we make molecules made of elements like carbon, nitrogen, and phosphorus, and attach them to metals). Most of these compounds are sensitive to air and water so we have special techniques to work with them. While it is difficult some days, I couldn’t imagine doing any other chemistry!

Back to potassium – why is potassium acetate important and why is it important as a fertilizer? Just like us, plants need potassium to grow big and strong, and potassium acetate is an environmentally-friendly and renewable source of potassium. It actually has been shown to be the best source of potassium for plants!

Currently, potassium acetate is made through the Monsanto or Cativa process. These are technical names for two reactions that make acetic acid, more commonly known as vinegar. The resulting acetic acid then must be taken to potassium acetate. This means that the synthesis requires two steps, and the chemicals used for this process are non-renewable; they come from fossil fuels unlike our bio-based ethanol.

In our reaction, we also generate hydrogen gas as a byproduct, and like potassium acetate, this can be sold commercially. Most of the hydrogen in the United States is made through a process called steam-reforming, which is dependent on fossil fuels. The process generates a mixture of hydrogen and carbon monoxide which together are called syngas. For applications requiring pure hydrogen – such as vehicle filling and chemical manufacturing – the hydrogen must be separated and pressurized contributing to the high costs. With the United States Department of Energy interested in driving the price of one kilogram of hydrogen down to $1 by 2030 due to the rapid growth of the hydrogen market (projected to be worth $11 billion by 2030!), our reaction has immense value in industry.

So far in my research, with the help of my undergraduate collaborator and other graduate students, I have been able to identify catalysts that allow us to take ethanol to potassium acetate and hydrogen. Currently, we are working on finding conditions that give us the best yields of both hydrogen and potassium acetate while identifying key chemical steps in the reaction.

Because the idea of moving chemistry out of the lab and into industry is important to my advisor, he encouraged my undergraduate collaborator, Shayna Kohl, and I to enter a venture pitch competition here at USC. Together, we showed that because we generate two value-added products, our process can be profitable and effective. While we did not win USC’s New Venture Seed Competition with our company, CornGas, it was a rewarding experience to work on the company plan based on research that we have done together. It was fascinating to work through challenges of taking research from lab scale to industrial scale, and I have a much greater respect for the soft skills required during the process as well as the technical ones.

I am excited to have a publication coming out later this year on this research. While I cannot discuss all of our findings, I am excited to be able to share all of my hard work here soon. It is amazing to look back at all the work that got me to this place and makes me excited for what is to come!

Rice Rander is supported by the Diane Sonosky Montgomery and Jerol Sonosky Graduate Fellowship for Environmental Sustainability Research.